Swift as the Wind

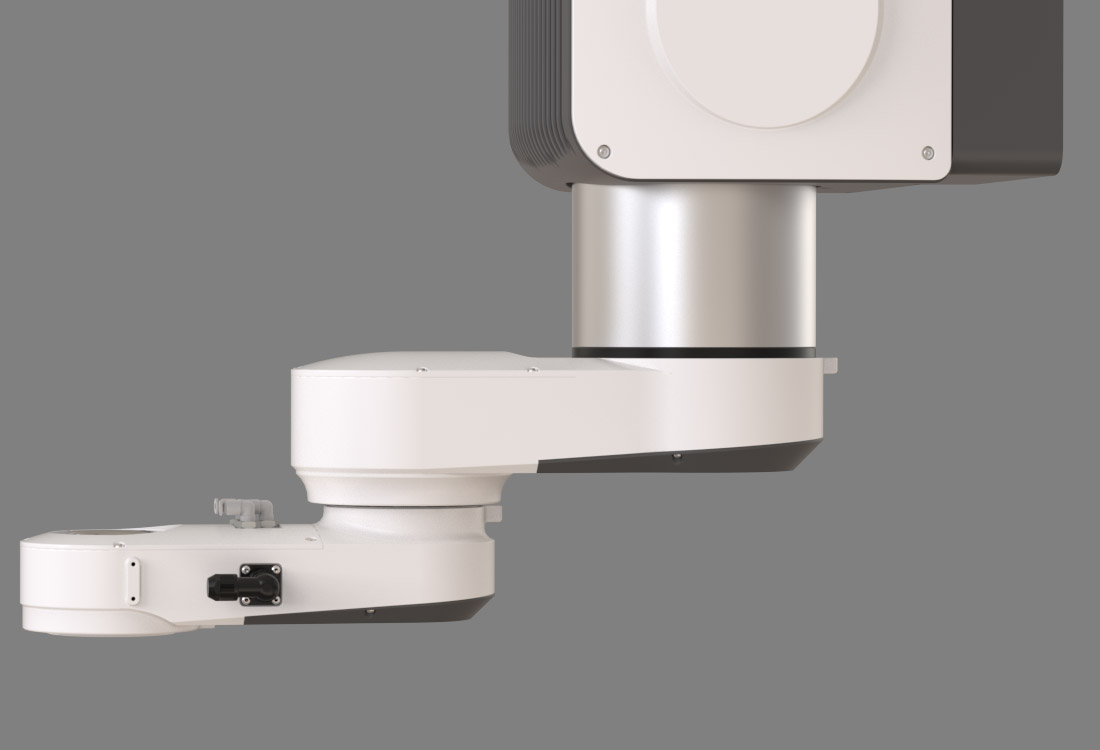

High-Speed SCARA SRX8-652

With a 0.26s standard cycle time, it pushes the limits of production capacity.

Steady as a Mountain

High rigidity eliminates end jitter,

significantly enhances precision, and fully ensures product yield.

Precise Placement

Repeatability of ±0.01mm,

coupled with stable stopping characteristics,

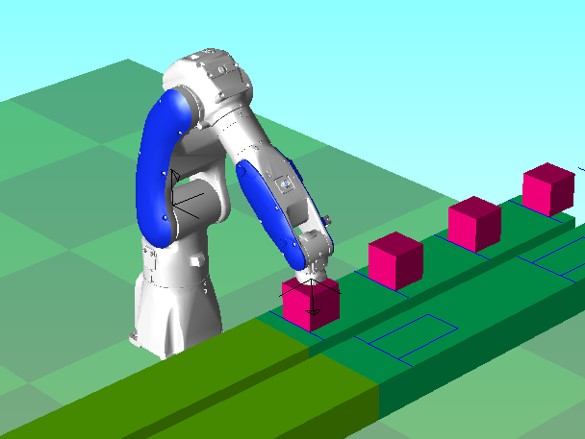

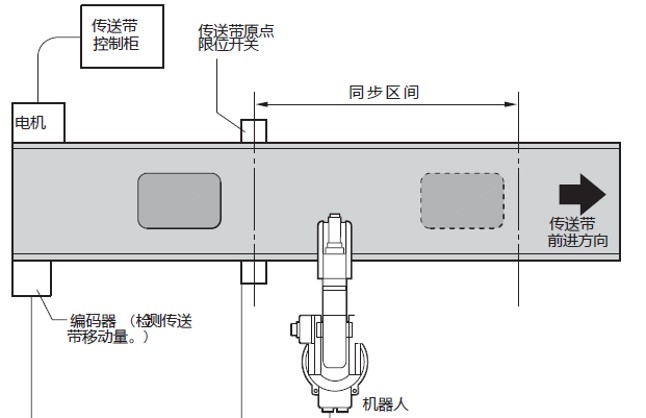

makes it especially suitable for fields like photovoltaics, new energy,

lithium batteries, packaging, and medical.

Consistently Reliable

Operates at full speed under high load over long periods, maintaining consistent stability to ensure production efficiency.

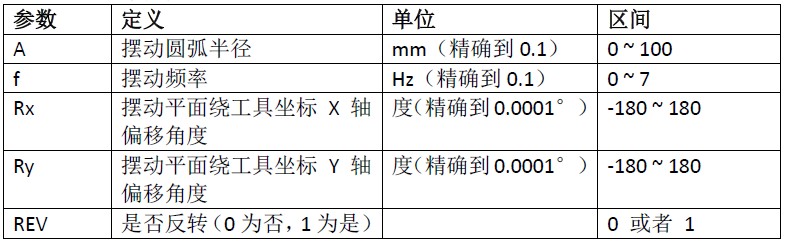

Customized Solutions

Personalized parameter customization tailored to

different application scenarios

for optimal cycle matching.

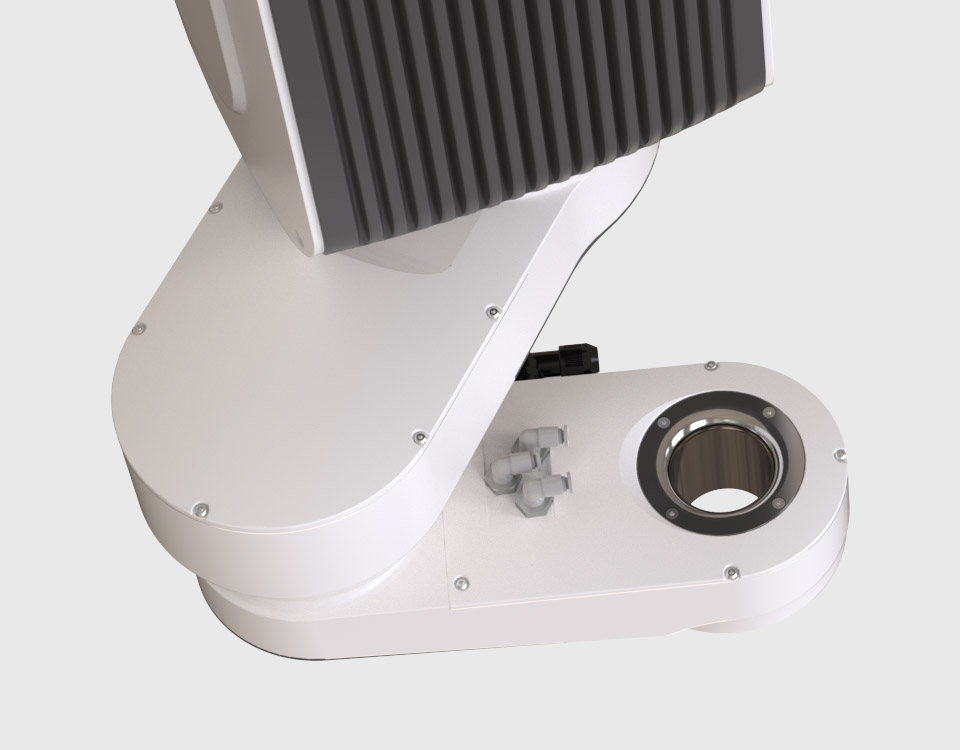

Ingress Protection Rating IP67

Resistant to Water and Dust

The smooth and streamlined structural design minimizes the number of exposed bolts,

preventing the accumulation of dust and cutting oil.

| Key Specifications of SRX8 | ||

|---|---|---|

| Model | SRX8-652 | |

| Maximum Load(kg) | 8kg | |

| Standard Cycle Time | 0.26s | |

| Degrees of Freedom | 4-axis | |

| Arm Length | J1+J2 | 650mm |

| Allowed Inertia at J4 | max | 0.45kg·㎡ |

| Repeatability (mm) | J1+J2 | ±0.015mm |

| J3 | ±0.01mm | |

| J4 | ±0.005° | |

| Body Weight (kg) | 29kg | |

| Key Specifications of SRX8 | ||

|---|---|---|

| Model | SRX8-652 | |

| Maximum Load(kg) | 8kg | |

| Standard Cycle Time | 0.26s | |

| Degrees of Freedom | 4-axis | |

| Arm Length | J1+J2 | 650mm |

| Allowed Inertia at J4 | max | 0.45kg·㎡ |

| Repeatability (mm) | J1+J2 | ±0.015mm |

| J3 | ±0.01mm | |

| J4 | ±0.005° | |

| Body Weight (kg) | 29kg | |

| Key Specifications of SRX8 | ||

|---|---|---|

| Model | SRX8-652 | |

| Maximum Load(kg) | 8kg | |

| Standard Cycle Time | 0.26s | |

| Degrees of Freedom | 4-axis | |

| Arm Length | J1+J2 | 650mm |

| Allowed Inertia at J4 | max | 0.45kg·㎡ |

| Repeatability (mm) | J1+J2 | ±0.015mm |

| J3 | ±0.01mm | |

| J4 | ±0.005° | |

| Body Weight (kg) | 29kg | |